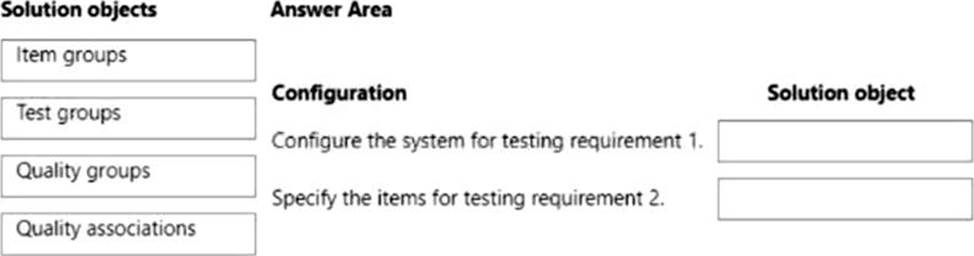

Which solution objects should you configure?

DRAG DROP

You need to configure quality controls.

Which solution objects should you configure? To answer, drag the appropriate solution objects to the correct configurations. Each solution object may be used once, more than once, or not at all. You may need to drag the split bar between panes or scroll to view content. NOTE: Each correct selection is worth one point.

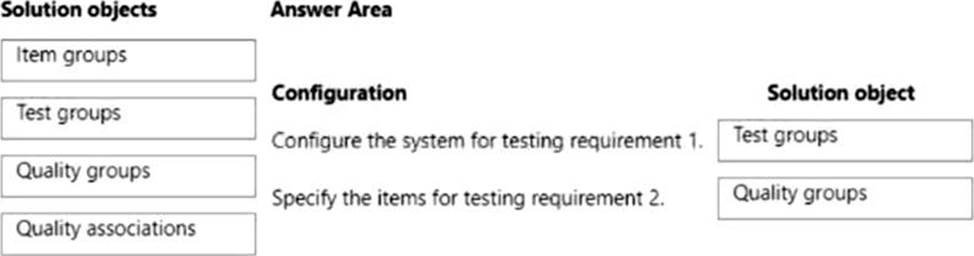

Answer:

Explanation:

Box 1: Test groups

Requirement 1: 100 percent of all nutritional supplements and 50 percent of all energy drinks must be tested when production orders are completed. After a product is in testing, 100 percent of all tests must be completed.

You use the Test groups page to set up, edit, and view test groups and the individual tests that are assigned to them. The upper part of the page shows the test groups, and the lower part shows the tests that are assigned to a selected test group.

You assign several policies to a test group, such as a sampling plan, an acceptable quality level (AQL), and the requirement for destructive testing. Then, when you assign an individual test to a test group, you define additional information, such as the sequence, documents, and validity dates. For a quantitative test, the information that you define also includes the acceptable measurement values. For a qualitative test, the information includes the test variable and default outcome.

The test group that is assigned to a quality order defines the default set of tests that must be performed on the specified item. However, you can add, delete, or change tests for the quality order. Test results are reported for each test on a quality order.

Box 2: Quality groups

Requirement 2: 75 percent of all nutritional supplements and energy drinks should be tested against their required tests during an outbound process.

Quality groups

A quality group represents common testing requirements for items.

Use and create item quality groups to logically group products so that they can be assigned to quality associations for the automatic generation of quality orders.

Example of an item quality group

A manufacturing company purchases various raw materials that have the same testing requirements for incoming inspection. Therefore, the company defines a quality group and then assigns the item numbers that are associated with the raw materials to that group. Later, the company purchases a new type of raw material that has the same testing requirements. Instead of setting up new testing requirements for the new material, the company adds the item number for the new material to the existing quality group.

Reference:

https://docs.microsoft.com/en-us/dynamics365/supply-chain/inventory/quality-management-processes

https://docs.microsoft.com/en-us/dynamics365/supply-chain/inventory/quality-groups

https://docs.microsoft.com/en-us/dynamics365/supply-chain/inventory/quality-test-groups

Latest MB-330 Dumps Valid Version with 198 Q&As

Latest And Valid Q&A | Instant Download | Once Fail, Full Refund